Clear Fiberglass Reinforced Plastics Panels

Clear Fiberglass Reinforced Plastics Panels

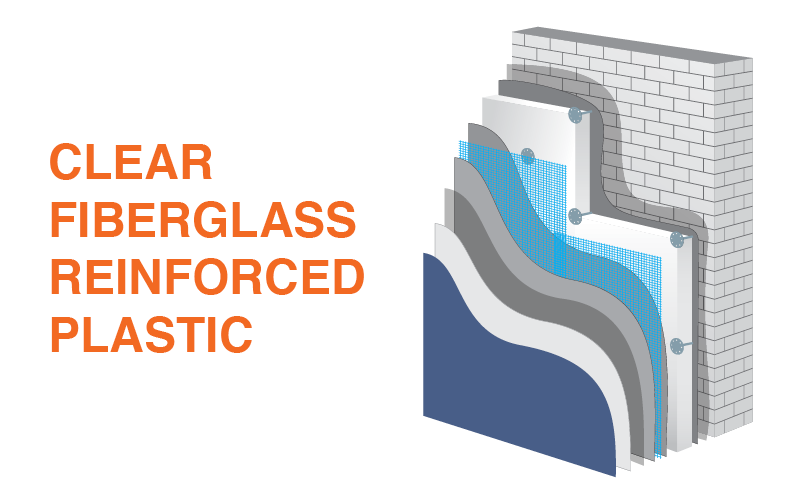

Fiberglass reinforced plastic products are made of fiberglass, which comes from a plastic or polymer matrix. Some of the materials used to make these types of products include phenolic, polyester, epoxy, polyimide, novolac, melamine, silicon and resin systems. Most formed fiberglass is laminated as well as given a protective coating in order to make it sturdier and protect it from weathering and possible damage.

What are panels used for?

Panels provide durability with extremely high strength and stiffness. Due to its high load capacity it can be used with confidence in structures where high load and wide support spans are required.

Where can we use FRP?

FRP is manufactured and tested to perform in locations such as: hospitals, schools, public restrooms, commercial kitchens, restaurants, correctional facilities, coolers and freezers, supermarkets, car washes, meat and dairy facilities and laboratories.

Why is FRP the better choice?

- Tough, strong and easy to clean

- Maximum sanitation protection and moisture resistance

- Highly impact resistance

- Resistant to scratches and abrasion

- Easy to clean

- Resists stains and will not corrode

- Low cost installation and minimum maintenance

FRP’s true purpose:

FRP provides extra protection. It is used in high danger areas. If the area is exposed to extreme weather condition, chemicals, electricity, etc. using fiberglass reinforced plastic panels will help protect and preserve the area.

This type of material resists denting, has low thermal expansion, is corrosion resistant, has insulating properties, is lightweight as well as stiff, and has a high impact tolerance. This product is also fire resistant and can insulate thermal and electric areas.