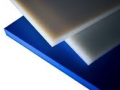

Nylon

Nylon is the generic designation for a family of synthetic polymers known generically as Polyamides. Nylons offer extremely good wear and impact resistance. They also withstand sustained contact with a wide variety of chemicals and offer a good operating temperature range.

Given its relative light weight and toughness Nylon is frequently used as replacement material for metal as gears, fittings, and bearings.

|

|

|

|

Nylon is one of the most widely used engineering thermoplastics. It offers an excellent combination of mechanical performance and cost. Cast Nylon (Type 6) and Extruded Nylon 101 (6/6) are the most common. These manufacturing methods are also combined with various fillers to achieve a number of additional attributes. MDS (molybdenum disulfide -MoS2) and NSM are common solid lubricant filled offerings. Oil filled and glass filled versions are available to provide additional options for lubricity and toughness. Other well-known family members include Nylon-11 and 12.

| ASTM or UL Test | Property | Nylon 6 | Nylon 6/6 | Nylatron | Nylatron |

| Manufacturing Process | Extruded | Cast | Cast | Cast | |

| Type | Unfilled | Unfilled | Moly-Filled | Solid Lubricant | |

| Color | Natural or Black | Natural | Grey | Grey | |

| D792 | (g/cm³) | 1.15 | 1.15 | 1.16 | 1.15 |

| D570 | Water Absorption, 24 hrs (%) |

0.3 | 0.3 | 0.3 | 0.25 |

| Saturation (%) | 7 | 7 | 7 | 7 | |

| D638 | Tensile Strength (psi) |

11,500 | 12,000 | 10,500 | 11,000 |

| D790 | Flexural Modulus (psi) |

450,000 | 500,000 | 400,000 | 400,000 |

| D785 | Hardness, Rockwell R |

M85 / R115 | R115 | R110 | R110 |

| D256 | IZOD Notched Impact (ft-lb/in) |

0.6 | 0.4 | 0.5 | 0.5 |

| D696 | Coefficient of Linear Thermal Expansion |

5.5 | 3.5 | 3.5 | 5 |

| (x 10-5 in./in./°F) | |||||

| D648 | Heat Deflection Temp (°F / °C) at 264 psi |

200 / 93 | 200 / 93 | 200 / 93 | 200 / 93 |

| Cost | $ | $ | $$ | $$ |

All properties are generalized. Material purchased may vary. You can request specification for products purchased.